3D Printing Explained

3D printing is a new technology that creates 3D objects by combining successive layers of material. These objects can have any shape, and making them requires the existence of a 3D model. The 3D printers aren’t similar with the printing devices we all know and like; it’s an industrial printer, an industrial robot.

3D printing works by adding material onto a powder bed, using several printer heads. This technology is already used in several industrial sectors, allowing people to create pane parts, jewelry, clothing and even medical devices.

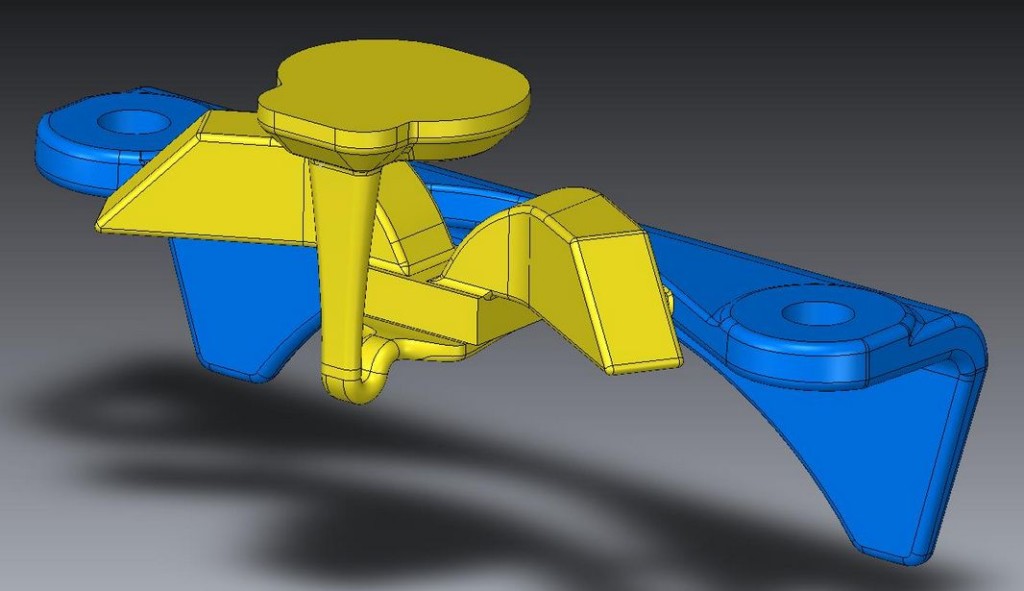

If you want to print a 3D object, you need to build a virtual blueprint of it using computer-aided design (CAD) software. The blueprint (a 3D model) is then translated into instructions which help the printer do its job. Several layers are built on top of each other and in the end the final product is finalized.

There is also a dark side of 3D printing, as people can create illegal objects like weapons using 3D printers. Of course, there is an endless list of good ways to use this technology, no matter if we are talking about industry, medicine or simply for having fun.

3D printers work by making use of additive manufacturing, which means that successive layers are added in order to form the final product. This is a different technology in comparison with subtractive manufacturing, where the object is made through cutting the raw material until it reaches the desired shape or size. 3D printers can use rubber, plastic, paper, polyurethane materials and even metals in order to build the desired object.

Last year, a team of researchers, engineers and dentists have created the first prosthetic beak for a bald eagle. NASA wants to test 3D printers that are supposed to help the astronauts build whatever they may need for their space missions. Researchers already talk about 3D printed meat, which would be created using proteins, or even 3D printing for fully furnished living rooms.

Right now these printers are quite expensive. As an example, a smaller printer which can be used to print small toys and objects costs around $1,000 whereas a more professional model which can create large objects can cost up to $60,000.

In the past years, 3D printing has also been used to create replacement part in the auto industry. Local Motors has created an entire car through 3D printing in just 6 days, for example. The car will need to pass several safety tests before being sold and driven on real roads all over the world, of course.

When it comes to printing houses, the entire process may last several months and even entire years because the 3D printing technology is at its beginning. But there is one Chinese company that has managed to print 10 simple houses in a single day. Each of these houses costs around $5,000. As you can imagine, 3D printers are of big interest for architects, because they see the potential of creating all sorts of innovative blueprints.

3D printers will surely prove their utility in the health care industry. Medical implants and body parts like teeth, hip joints and knees are being produced by 3D printers today. The technology will also be utilized to create the organs that will be used in transplants, but the FDA has to test and approve it first.